Carbon Footprint of Jewelry: Key Facts

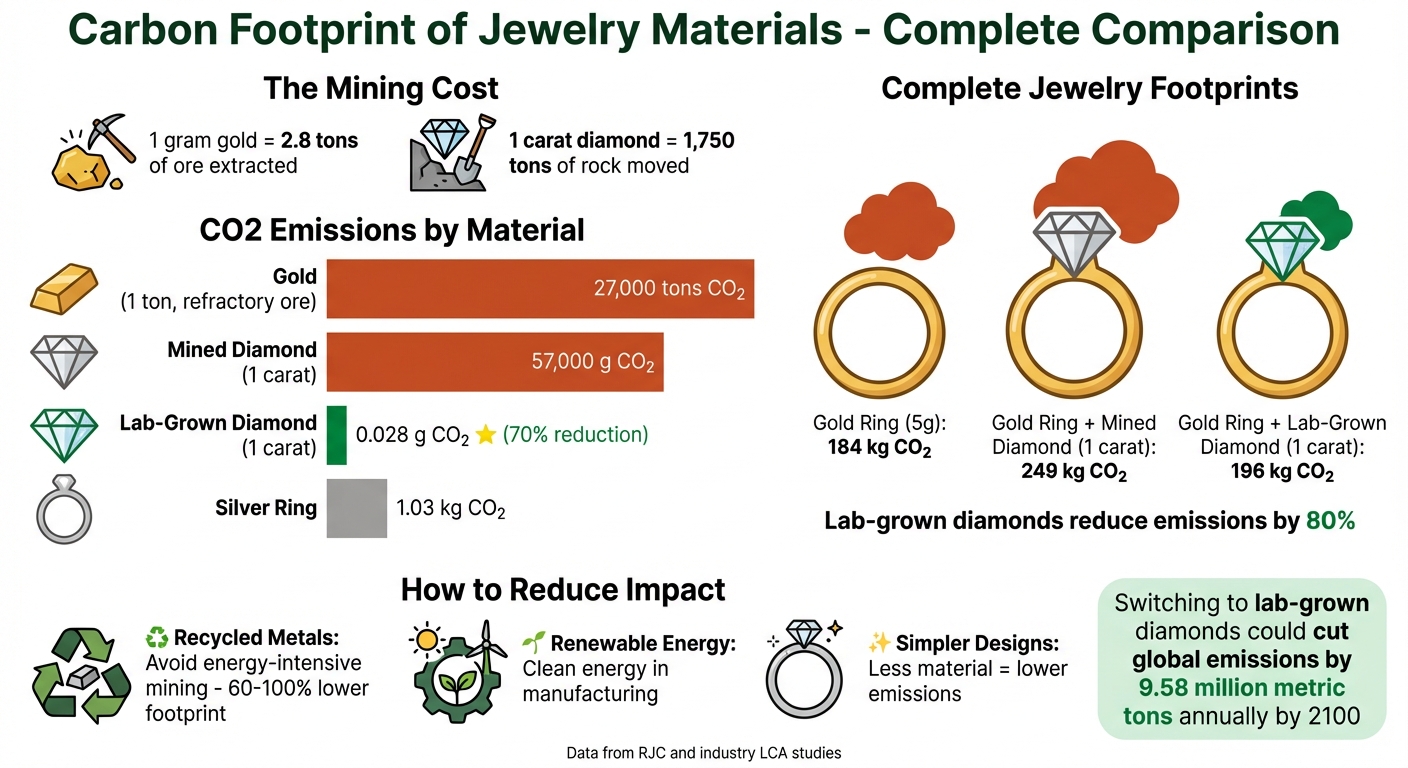

- Mining Impact: Extracting 1 gram of gold requires 2.8 tons of ore, while mining 1 carat of diamond involves moving 1,750 tons of rock. These processes drive up emissions and cause long-term damage.

- Lab-Grown Diamonds: These can cut emissions by up to 70% compared to mined diamonds.

-

Material Footprints:

- Gold: Produces up to 27,000 tons of CO2 per ton of refractory ore.

- Mined Diamonds: Emit 57,000 grams of greenhouse gases per carat, while lab-grown diamonds emit only 0.028 grams per carat.

- Silver: Has a smaller footprint compared to gold or platinum.

- Jewelry Type Matters: A 5g gold ring generates ~184 kg CO2, but adding a 1-carat mined diamond raises it to ~249 kg CO2. Using lab-grown diamonds reduces this to ~196 kg CO2.

-

Reduction Strategies:

- Recycled Metals: Avoid energy-intensive mining.

- Renewable Energy: Use clean energy in manufacturing.

- Simpler Designs: Require fewer materials and energy.

Quick Comparison

| Material/Process | CO2 Emissions (approx.) | Other Impacts |

|---|---|---|

| Gold (1 ton, refractory) | 27,000 tons CO2 | High energy use for refining |

| Mined Diamond (1 carat) | 57,000 g CO2 | 2.63 tons of mineral waste |

| Lab-Grown Diamond (1 carat) | 0.028 g CO2 | Minimal waste and water usage |

| Silver Ring | ~1.03 kg CO2 | Lower impact than gold or platinum |

Switching to recycled metals and lab-grown gemstones can drastically lower emissions. Consumers and manufacturers alike can make choices to support lower-impact jewelry.

Carbon Footprint Comparison of Jewelry Materials and Types

Natural vs Lab-Grown Diamonds Which Has Lower Carbon Emissions?

sbb-itb-1bb5b78

Carbon Emissions in Jewelry Production

Jewelry production contributes to carbon emissions at every step, but the scale of the impact depends heavily on the stage of the supply chain. The bulk of emissions come from raw material extraction, with manufacturing adding a smaller but still meaningful share. Here's a closer look at the emissions tied to these processes.

Mining and Material Extraction

Mining and refining precious metals are the primary sources of carbon emissions in jewelry production. Studies reveal that these stages can account for 60% to nearly 100% of the environmental impact across the supply chain. This is largely due to the energy-intensive nature of extracting virgin metals, which involves heavy machinery, ore processing, and chemical refining.

The refining process, in particular, demands vast amounts of energy. High-temperature furnaces and chemical treatments - both of which often rely on fossil fuels for heat or electricity - are major contributors. Globally, the metals and mining sector emits 3.4 gigatons of CO2-equivalent emissions annually and uses about 9.5% of the world’s total energy. Precious metals like gold and platinum come with some of the highest environmental costs per kilogram in the entire metals industry.

Once the raw materials are extracted, the manufacturing process adds its own layer of emissions.

Production and Manufacturing

While manufacturing has a smaller carbon footprint compared to mining, it still plays a significant role in emissions. Most of the impact comes from electricity used for shaping, cutting, and assembling jewelry. Additionally, the use of industrial gases and harmful chemicals during production further adds to the environmental burden.

A notable example is diamond cutting, with 90% of this activity concentrated in India. This geographic centralization creates a significant emissions hotspot in the mid-stream supply chain. However, companies can take steps to reduce these emissions, such as improving energy efficiency in their manufacturing processes.

Carbon Emissions by Material

Continuing from our earlier discussion on production stages, let's take a closer look at how different materials used in jewelry contribute to carbon emissions. The carbon footprint of these materials depends on factors like extraction methods, processing techniques, and whether the material is mined or lab-grown.

Gold, Silver, and Platinum

Gold stands out as one of the most carbon-heavy materials in jewelry production. To put it into perspective, extracting one tonne of gold from non-refractory ore results in approximately 18,000 tonnes of CO₂-equivalent emissions. Given that typical gold ore contains only about 3.5 grams of gold per tonne, enormous quantities of ore must be processed to extract even a small amount. The situation worsens with refractory ores, which require additional steps like flotation and pressure oxidation. These processes push emissions up by roughly 50%, resulting in about 27,000 tonnes of CO₂-equivalent per tonne of gold. On a per-kilogram basis, both gold and platinum rank among the most environmentally taxing materials due to the energy-intensive processes required for purification and refining.

Mined vs. Lab-Grown Gemstones

When comparing mined and lab-grown gemstones, the difference in emissions is staggering. Mined diamonds are responsible for 57,000 grams of greenhouse gases, generate 2.63 tonnes of mineral waste, and consume 0.48 m³ of water per carat. In contrast, lab-grown diamonds - especially those produced using clean energy - emit just 0.028 grams of greenhouse gases, create only 0.0006 tonnes of waste, and require 0.07 m³ of water per carat. That’s a reduction of over 2 million times in emissions. According to research, switching from mined to lab-grown diamonds could potentially cut global greenhouse gas emissions by 9.58 million metric tons annually by 2100.

Carbon Footprint by Jewelry Type

The carbon footprint of a jewelry piece largely depends on its metal weight and the type of gemstone it includes. For instance, a simple 5-gram gold ring generates about 184 kg of CO₂ emissions, but add a 1-carat mined diamond, and the emissions jump to approximately 249 kg CO₂.

The type of metal and gemstone used significantly influences the overall environmental impact. For example, a silver ring has a much smaller footprint, producing only 1.03 kg CO₂. Larger pieces, like necklaces or bracelets, naturally result in higher emissions because of the greater amount of metal involved. These figures highlight how design decisions and material choices play a direct role in shaping a piece's carbon emissions. The table below offers a clear comparison of the carbon footprints associated with various types of jewelry.

Product Comparisons Table

| Jewelry Item | Material Composition | Estimated Carbon Footprint |

|---|---|---|

| Gold Ring (5g) | Mined gold only | ~184 kg CO₂ |

| Gold Ring (5g) + Mined Diamond (1 carat) | Mined gold + mined diamond | ~249 kg CO₂ |

| Gold Ring (5g) + Lab-Grown Diamond (1 carat) | Mined gold + lab-grown diamond | ~196 kg CO₂ |

| Silver Ring | Mined silver | ~1.03 kg CO₂ |

Key Insight: Choosing lab-grown diamonds instead of mined ones can reduce diamond-related emissions by around 80%. Additionally, using recycled metals or other sustainable materials can significantly lower the carbon footprint of jewelry. These choices not only benefit the environment but also make a strong statement about responsible design.

How to Reduce Carbon Footprints in Jewelry

Jewelry manufacturers can take meaningful steps to lower carbon emissions by improving material sourcing, energy consumption, and design practices. The 2024 Code of Practices mandates that all Responsible Jewellery Council (RJC) certified members disclose their Scope 1 and Scope 2 emissions. This requirement is driving measurable progress toward reducing environmental impacts.

Recycled Metals and Materials

Using recycled gold and silver is a practical way to cut down on emissions. These metals avoid the energy-heavy processes involved in mining and refining, significantly reducing their carbon footprint. Interestingly, metals reclaimed from jewelry production scraps often have a smaller environmental impact compared to those sourced from non-jewelry waste streams, like electronic waste. This approach not only conserves resources but also supports a more sustainable supply chain.

Renewable Energy in Manufacturing

Electricity usage during manufacturing is a major contributor to emissions, but this can be addressed with renewable energy. A Life Cycle Assessment reveals that reducing manufacturing electricity consumption - especially by switching to renewable energy - can substantially lower a product's overall footprint.

"Reducing electricity consumption in manufacturing is also one option for the company since it could be activated directly"

- Thammaraksa et al. (Journal of Cleaner Production)

By integrating renewable energy into production processes, manufacturers can make strides toward carbon neutrality. These energy strategies also complement design innovations that aim to minimize material usage.

Simplified and Minimalist Designs

Streamlined jewelry designs are another way to reduce emissions. By requiring less material and energy to create, minimalist pieces help lower the overall carbon footprint. Thoughtful design choices - like reducing metal weight - can cut down on resource use during production and transportation. These benefits extend throughout the product's lifecycle, making simpler designs an environmentally conscious choice.

Benefits of Carbon-Neutral Jewelry

Adopting carbon-neutral practices brings more than just environmental perks. The RJC, which now boasts over 2,000 member companies, has set rigorous standards for sustainability. For example, an independent evaluation of the Peruvian mining company Minera Yanaquihua S.A.C. in 2015 by the University of Queensland highlighted how RJC certification led to reduced environmental risks and better practices in artisanal and small-scale mining.

Consumer demand for transparency is also driving these changes. Shoppers increasingly prefer jewelry that aligns with their environmental values, giving companies that embrace sustainable practices a competitive edge. At Rokshok, we align with these trends by crafting premium moissanite jewelry with eco-conscious methods. These efforts are part of a broader commitment to sustainable production.

| Benefit | Impact | Example |

|---|---|---|

| Emissions Reduction | 60%–100% lower footprint when using recycled metals vs. mined | Recycled gold avoids energy-intensive mining and refining processes |

| Supply Chain Transparency | Better traceability and risk management | RJC certification requires origin tracking and KYC protocols |

| Market Positioning | Meeting growing demand for sustainable products | Over 2,000 companies are RJC-certified |

| Operational Control | Direct emissions reduction in manufacturing | Adoption of renewable energy in production facilities |

Conclusion

Mining and refining precious metals account for a staggering 60% to nearly 100% of total emissions across the supply chain. This makes the sourcing of materials the most critical factor when assessing the carbon footprint of any jewelry piece.

Choosing recycled gold and silver can help sidestep the energy-heavy extraction processes that contribute to these emissions. Recycled metals not only reduce environmental damage but also pave the way for more sustainable practices. Additionally, incorporating renewable energy and resource-efficient designs can further cut emissions, laying the groundwork for meaningful industry change.

Today, over 2,000 companies are RJC-certified, adhering to strict standards of transparency and accountability. This growing commitment is reshaping how the sector operates, fostering greater trust and responsibility.

Consumers, too, hold immense power to influence the industry's direction. By prioritizing recycled materials, verifying certifications, and supporting brands that embrace renewable energy, they can drive demand for more responsible practices. For example, Rokshok’s premium moissanite jewelry exemplifies this approach, offering luxurious, eco-conscious alternatives with minimal environmental impact. Armed with this understanding, consumers can align their choices with their environmental values and help propel the industry toward a more sustainable future.

FAQs

What is the environmental impact of lab-grown diamonds compared to mined diamonds?

Lab-grown diamonds generally have a far smaller carbon footprint compared to their mined counterparts. To put it into perspective, producing one carat of a lab-grown diamond can result in as little as 0.03 kilograms of CO2, whereas mining a single carat generates around 160 kilograms of CO2. That said, the environmental impact largely hinges on the energy sources powering the production process. Using renewable energy keeps emissions low, while reliance on fossil fuels can significantly increase them.

Opting for lab-grown diamonds - particularly those crafted with sustainable energy - offers a way to indulge in stunning, high-quality jewelry while aligning with eco-conscious and ethical values.

What are the environmental benefits of using recycled metals in jewelry?

Recycled metals bring a host of environmental benefits to jewelry production. For starters, they significantly reduce the need for mining - a process notorious for its heavy carbon emissions. Extracting precious metals like gold can emit tens of thousands of tons of CO₂ per ton mined, while also contributing to deforestation and the destruction of natural habitats. By opting for recycled metals, these harmful impacts are minimized, conserving natural resources and cutting down on water and energy consumption during manufacturing.

This practice also aligns with the principles of a circular economy, where waste is minimized, and materials are reused. For the jewelry industry, this means a smaller carbon footprint and a stronger appeal to consumers who prioritize eco-conscious and ethically sourced products. Recycled metals enable jewelers to craft exquisite, high-quality pieces while staying committed to environmental responsibility.

What steps can I take to lower the environmental impact of my jewelry purchases?

To make more mindful choices with your jewelry purchases, focus on pieces crafted from materials sourced responsibly and made using earth-friendly methods. Seek out brands that actively work to lower their carbon footprint through initiatives like carbon neutrality and ethical production processes.

Opting for jewelry from companies like Rokshok, which emphasize sustainability, allows you to enjoy stunning, well-made designs while supporting responsible practices. Another tip? Go for timeless, sturdy pieces that match your style - this encourages long-term use and helps cut down on waste.